Sometimes brakes are necessary.

For example, when you are driving too fast and rocketing into a school-reduced speed zone.

Or when operating a Johnson Press punch press with a rated tonnage that ranges from 10 to over 200 tons (depending on the particular model).

So, to slow down and save lives, we examine common issues with the brake monitoring system on a Johnson Press, specifically the reset.

We explore when this is necessary and how to do it.

First, let’s get broad.

Common Issues With the Johnson Press Brake Monitoring System

For less experienced machinists or highly skilled ones new to a punch press, here are some common Johnson Press brake issues:

- Brake Lamp Activation: The “Brake” lamp lights up, indicating the system has tripped and the press is inoperable.

- Erratic Stopping: The press may stop inconsistently or not at all, suggesting a malfunction in the brake or limit switches.

- Failure to Reset: The brake monitoring system may not reset properly, preventing the press from resuming normal operation.

If any of these issues occur, a thorough inspection and reset may be necessary.

Reasons for Johnson Press Brake Monitoring Reset

We’ve looked at common brake issues. Let’s get a little more detail on what might cause a brake reset.

- Tripped Brake Monitoring System: The system may trip if the brake does not function correctly, indicated by the “Brake” lamp lighting up, rendering the press inoperable (see above).

- Safety Compliance: Resetting ensures that the press operates safely and adheres to operational standards after an issue or maintenance to the machine.

- Operational Readiness: A reset is necessary to restore functionality and allow the press to resume normal operations after troubleshooting or adjustments.

On the third point above, what constitutes “adjustments?”

These could be changes to the brake system, clutch settings or limit switches.

It’s a good idea to always refer to the maintenance logs and procedures to determine if a reset is necessary after any such adjustments.

So now we know the problem. What’s the solution?

Safe Procedure for Johnson Press Brake Monitoring Reset

Here’s the step-by-step…

- Ensure Safety First: Before starting, lock out the disconnect switch and block the ram up to prevent accidental movement.

- Check Manual Test Plungers: Depress both manual test plungers on the solenoid valve to open the brake shoes and inspect the brake lining wear.

- Follow Reset Steps:

- Turn the run/reset selector to “reset.”

- Place the press in “Inch” mode and start the motor.

- Inch the press to the top of the stroke.

- Turn the run/reset selector back to “run.”

- Select the desired mode of operation.

But wait…

…You might need replacement parts for your Johnson Press brake reset!

Parts to Consider for Johnson Press Punch Press Brake System Reset

What might those parts be?

- Brake Linings: If the linings show signs of wear or uneven thickness, replacement may be necessary.

- Limit Switches: If the limit switches are not functioning correctly, new switches may need to be purchased.

- Brake Spring: A new brake spring may be required if the existing one is worn or not providing adequate compression.

- Clutch Components: If the clutch is not releasing properly, parts such as friction discs or springs may need replacement.

Johnson Press was a company known for producing a range of mechanical and hydraulic presses used in various industrial applications.

Their machinery was primarily manufactured in the mid-20th century, from the 1940s to the 1980s.

Where do I find JP parts in the 21st century!?

LeBlond Provides Johnson Press OES Parts

We may be known for lathes, but LeBlond also provides Original Equipment Supplier parts for a variety of machine lines.

Like Johnson Press.

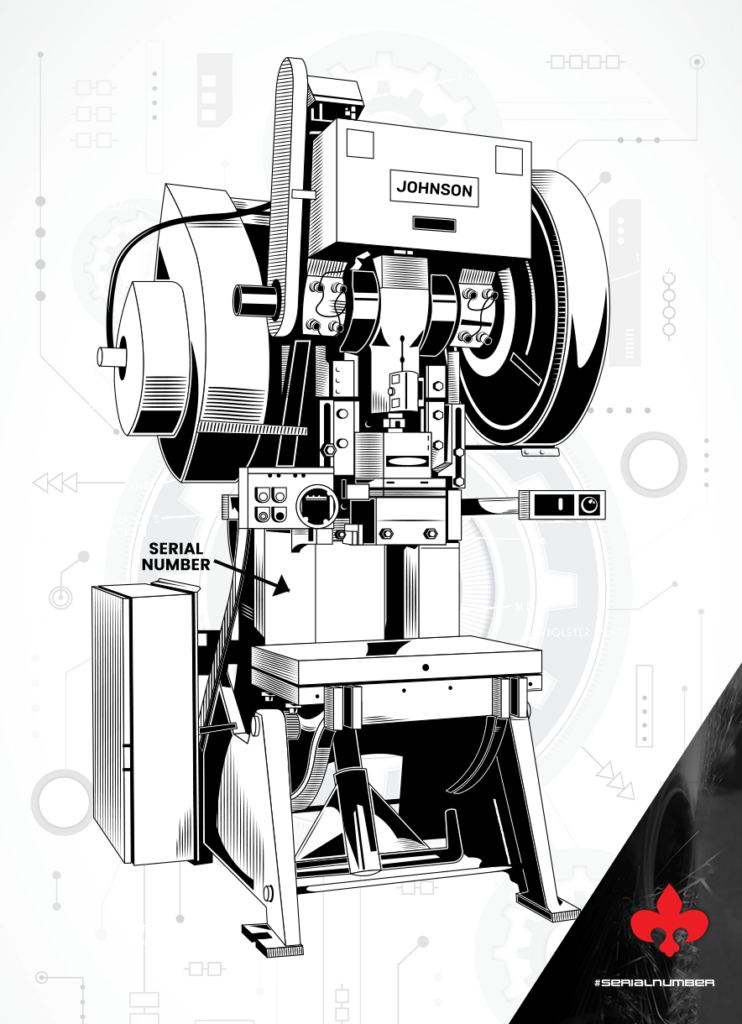

We will need your JP punch press serial number to get you parts. You can find it here:

If you need affordable Johnson Press OES parts,

- Order common replacement parts ONLINE.

- If you can’t find your part from our Inventory Available feature, call us at +1 (888) 532-5663 (Monday – Friday 8am – 5pm ET)

- Or just leave a comment below.

We look forward to hearing from you!