BC Bench Center & Surface Plate Information

K.O. LEE Small Tools: Bench Center and Surface Plate

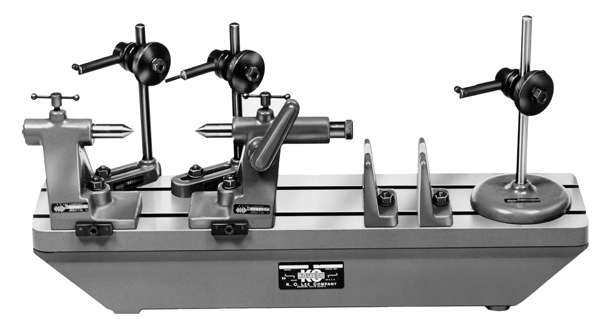

K.O. LEE Bench Center and Surface Plate provides an accurate means for inspection of all types of work. Work pieces can be mounted between centers, in V-rests or on a precision ground surface plate. Runout is shown on the dial indicator, as work is rotated by hand. Side runout or camming action can be checked with a second indicator. Parts without centers can be easily checked with the work holding V-rests, which are furnished as standard equipment.

Rigidly mounted on base with top and side locks, tailstocks can be positioned any place on the T-slot. The BC22R quick release tailstock has an adjustable setting for spring load. Spring adjustment can be made without changing relation of center to work. Work can be placed in position or removed easily with the use of the quick release lever. The centers are produced from an alloy steel, which has been hardened and precision ground. Optional carbide centers are available.

Tolerance for flatness on the surface plate is 0.0002″ (.005mm) or les per 12″ (304.8mm).

Use of unit is not restricted to one indicator. Three indicator stands are standard with the BC3 and can be positioned any place on the surface plate. The dial holding rod can be clamped at any height and angle and used on either side. Dial gauge pointer conveniently contacts piece. Dial indicators are not furnished with this unit.

Specifications

- Distance between centers

- Centerline height from center to plate

- Diameter of work over surface plate

- Length & width of surface plate

- Net weight

- Shipping weight

- 22″ (558.8mm)

- 4.130″ (104.9mm)

- 8.25″ (205.6mm)

- 7″ x 28″ (178 x 711mm)

- 102 lbs. (46kg)

- 125 lbs. (57kg)

Also Included

- S895 wrench

- 3/16″ hex wrench

- B855W open end wrench

- BC7P plain cross arm (used with BC71 checking stand)

- BC7T threaded cross arm (used with BC71 checking stand)