Stay Safe, Machine On, With These Lathe Safety Tips Most safety precautions machinists take today are a result of someone learning from a past mistake or oversight. Those lessons are passed down from old-timers to green newbies, as well as through industry...

Scott Hasson

5 Telltale Signs of Tool Wear Every Professional Machinist Should Recognize

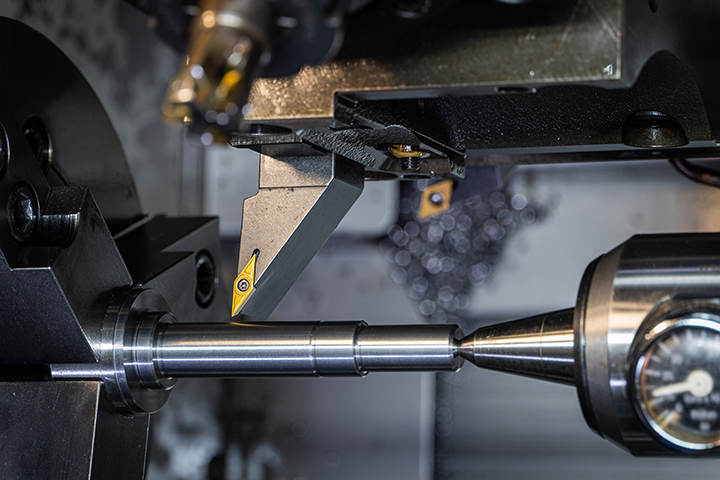

Signs of Tool Wear Machinists strive for perfection in every cut. Even the slightest deviation in precision metalworking can mean the difference between a flawless part and costly rework. Tool wear is inevitable, but early detection and correction can save valuable...

Mastering Machining Feeds, Speeds, and Depth of Cut

Don’t Get Haunted by Flawed Lathe Practices Even the most experienced machinist can be haunted by ghosts of poor performance — chatter marks that refuse to vanish, overheated tools that wear out too soon, or parts that just won’t meet spec. In the spirit of Halloween,...

5 Tips to Manage Tool Overhang in Lathe Metalworking

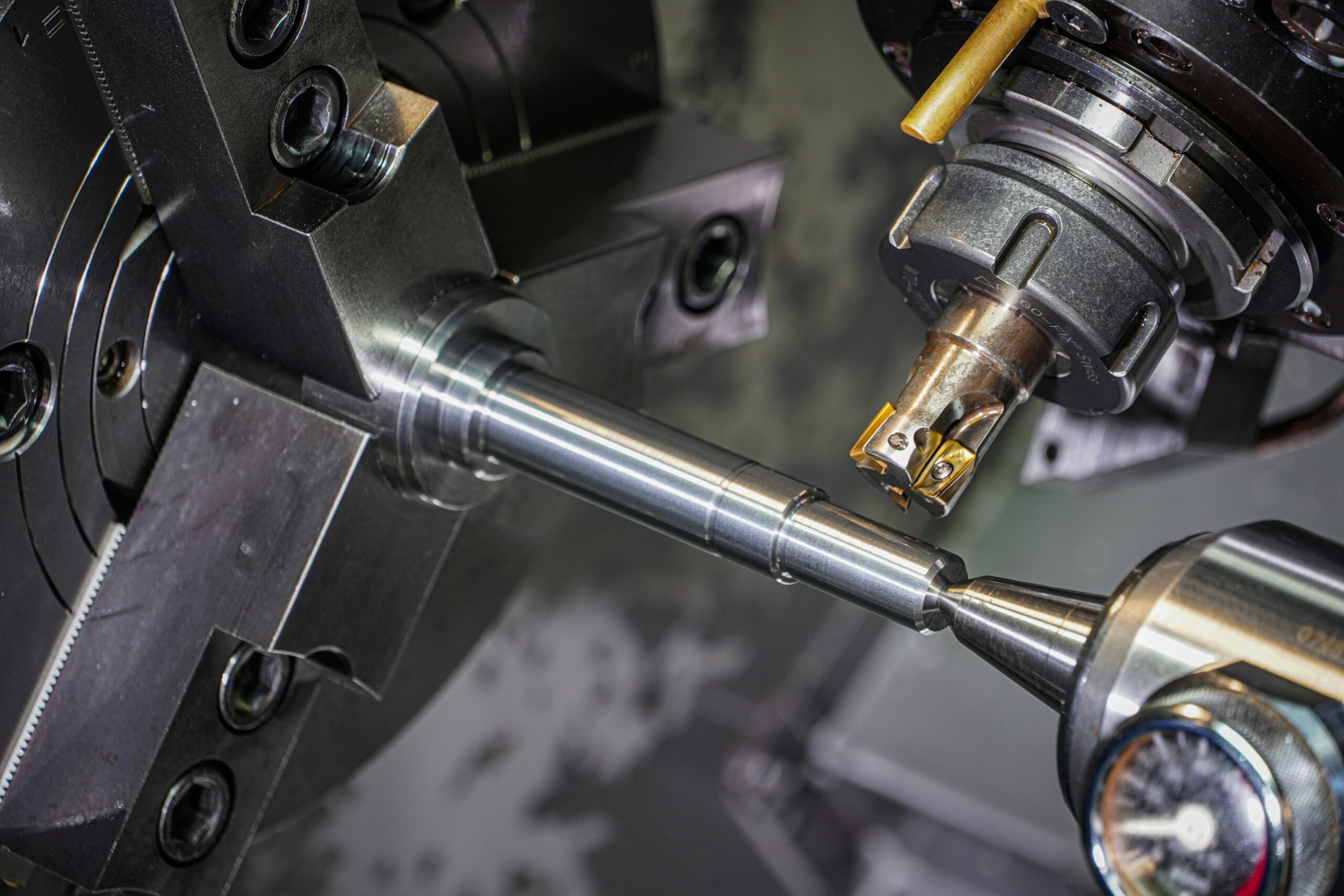

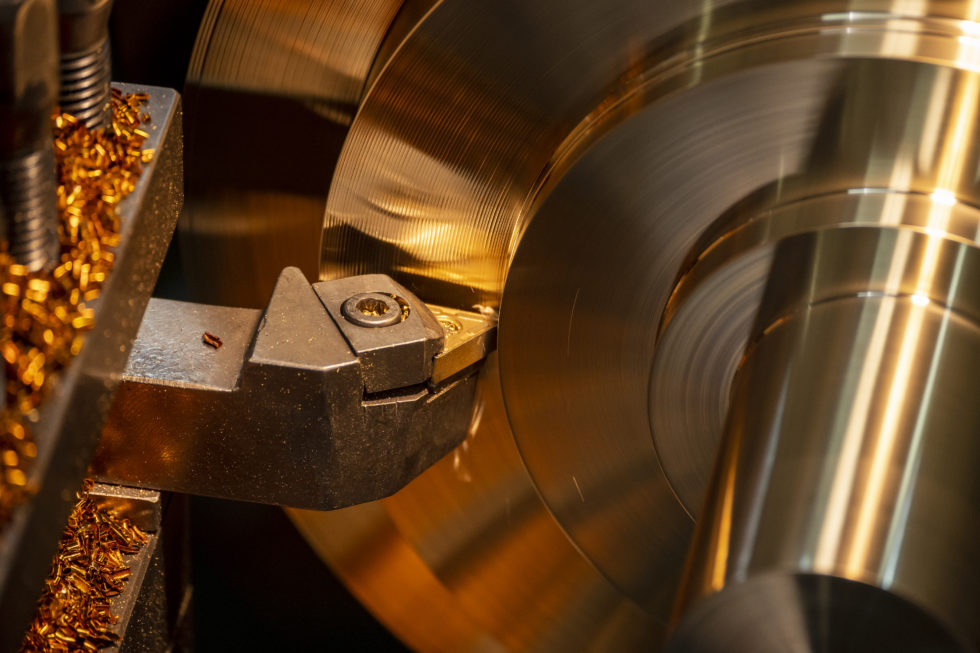

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

Lathes Get Machining Done

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

7 Essential Lathe Maintenance Tips for Smooth, Accurate Machining

A well-maintained lathe doesn’t just run better—it lasts longer, performs more accurately, and reduces downtime. Whether you’re operating a manual machine or a CNC lathe, implementing a structured maintenance routine is critical.

Tips for a Smooth Industrial Lathe Installation

So, you’ve taken the first steps in preparing for a lathe installation—you’ve identified the equipment weight, contacted a rigging company, and confirmed that disassembly and fluid drainage are (mostly) optional. Great! But the process doesn’t stop there. A successful...

5 Easy Tips for Extending the Life of Your Lathe

When the first explorers of America set out to find the Fountain of Youth, they never would have expected it right in the middle of a machine shop. The key to a lathe’s long life is through sticking to five easy lathe maintenance tips. An experienced machinist must...

Mastering Chip Control

Metalworking lathes are versatile machines used primarily for shaping metal and other solid materials. They are essential in various industries for machining parts using techniques such as: Turning, Facing, Drilling, Knurling, Parting, Taper Turning and Thread Cutting.