Your K.O. Lee tool & cutter grinder’s workhead is locked up.

You’re staring down a bill of around $30k for a new machine that is used to sharpen, shape and recondition cutting tools such as drills, milling cutters, reamers, taps and others.

But here’s the truth: you may not need one.

Call LeBlond’s service team. They can assess your situation and the option to rebuild your K.O. Lee workhead.

The Warning Signs

Your workhead is screaming for help if:

* You can’t turn the spindle by hand

* The drive V-belt keeps popping and breaking apart

* Your tooling shows runout (translation: your spindle isn’t running true)

* Rust has invaded your bearings

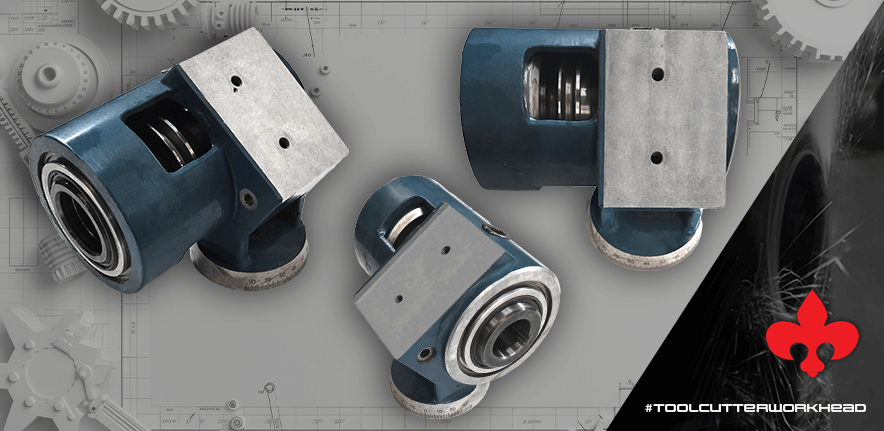

Inside the K.O. Lee Tool Cutter Workhead Rebuild Process

We strip down your workhead to its core components. The cast aluminum housing usually survives, but everything else gets a hard look.

Most rebuilds focus on:

* Installing new bearings and seals

* Replacing damaged spindles

* Setting precise preload tolerances

* Testing for zero runout

The Test Chamber

Your rebuilt workhead isn’t leaving our shop until it passes our thorough testing protocol:

* Variable speed drive motor testing

* Temperature monitoring (111°F/44°C max)

* Precision runout testing on a granite table

* Zero-tolerance policy for bearing noise or vibration

The Real Numbers

Let’s talk ROI:

* New Tool & Cutter Grinder: Around $30k

* Standard Workhead Rebuild: Few Thousands

* Warranty: 60 days

* Expected Lifespan: 3-4 years with proper maintenance

Maintaining Your Investment

Want to maximize your rebuild’s lifespan? Follow these critical steps:

* Clean the workhead after every use

* Blow out debris regularly

* Check spindle runout before each operation

* Monitor coolant infiltration

* Stay within the 400 RPM speed limit

The Bottom Line

A rebuilt workhead delivers precision performance around 10% of a new machine’s cost. Your rebuilt unit will handle everything from basic tool sharpening to precision gear cutting, maintaining zero runout for perfect cuts every time.

Don’t trash your tool & cutter grinder when the workhead fails. A professional rebuild will get you back to making chips for a fraction of the cost of new equipment.

Need a K.O. Tool & Cutter Grinder Workhead Rebuild?

- Call +1 (888) 532-5663 (Monday – Friday 8am-5pm ET) and select Option 3.

- Or leave a comment below!

We look forward to hearing from you!

Thank you for sharing ,always invaluable and helpful information on efficient time saving opportunities , and we all know what that saves

Thanks Marc!