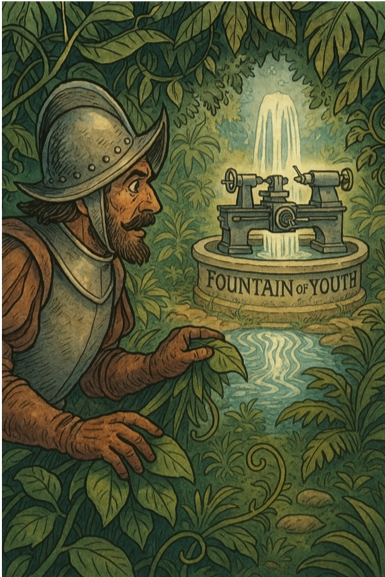

When the first explorers of America set out to find the Fountain of Youth, they never would have expected it right in the middle of a machine shop. The key to a lathe’s long life is through sticking to five easy lathe maintenance tips. An experienced machinist must prioritize regular lathe inspection, monitoring, and maintenance to ensure both precision and reliability when producing metal parts.

On the Level

One of the most critical aspects to extend a lathe’s life is verifying machine leveling and alignment. If the engine lathe is not properly leveled or if the headstock and tailstock are misaligned, the result can be tapered parts, inconsistent cuts, or chatter. Periodic checks using precision levels and test cuts help maintain alignment and machining accuracy. Learn how to level your lathe with our instructional video.

Tooling’s the Name, Don’t Wear it Out

Equally important is the consistent monitoring of tooling and insert wear. Tools that are chipped, dulled, or worn can drastically affect surface finish, dimensional precision, and even cause damage to the machine or part. By keeping track of tool wear across various materials and operations—such as roughing versus finishing—machinists can better predict tool life and maintain consistent quality.

Proud to be a Grease Monkey

The condition of the lubrication system is another key maintenance area. Proper lubrication of the ways, spindle, and gearbox ensures smooth operation and extends the life of the machine. Machinists should routinely inspect oil levels, check sight glasses, clean wipers, and watch for signs of contamination or leaks. Neglecting lubrication can result in excessive wear on guideways, leadscrews, and bearings—leading to costly downtime and repairs.

Inspection Drives Perfection

In addition to lubrication, inspecting mechanical components such as lead screws, cross-slide gibs, compound gibs, and the tailstock is essential. These elements must move smoothly and consistently without excessive backlash or resistance. Any unusual vibration, noise, or heat during operation could indicate internal mechanical issues that require prompt attention.

Take Time to Get Technical

Finally, accuracy verification should be part of the machinist’s regular workflow. Using precision instruments like micrometers, dial indicators, and test bars helps confirm that the lathe maintains tight tolerances. Cutting occasional test pieces and checking them for surface finish, concentricity, and dimension allows early detection of deviations and reduces scrap.

The search for the lathe Fountain of Youth may be ongoing. A disciplined approach to inspection, monitoring, and maintenance not only ensures the longevity of the engine lathe but also safeguards the quality of the machined parts. By staying vigilant in these five areas, a machinist upholds both safety and excellence on the shop floor. Knowing these pro tips will make you the machine shop conquistador.