LeBlond Ltd., a supplier of LeBlond lathes, K.O. Lee grinders and OEM service parts, has introduced a practical line of K.O. Lee Economy Mandrels that are time-tested, “best-in-class” machine tools with the quality and durability inherent in the LeBlond and K.O. Lee names. K.O. Lee, a subsidiary of LeBlond Ltd., is part of great machine tool tradition that dates back to 1887.

“With the addition of the Economy Mandrel line to complement our best-in-class K.O. Lee Expanding Mandrels, LeBlond is now the one source for all your mandrel requirements,” said Jon Tallman, President of LeBlond Ltd.

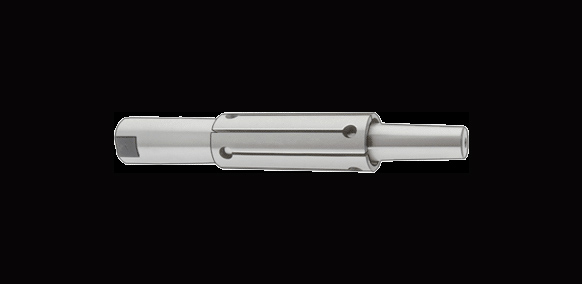

Used in production lines, tool rooms and home work shops, K.O. Lee Economy Mandrels feature expanding, solid and expanding-end mandrels. The three models differ in how they hold and attach to a part. Expanding mandrels have a wide range of expansion and high levels of concentricity featuring 10 tapered arbors (or shafts) from 5” to 17” with a slotted sleeve that expands from ½” to 3-3/4” to fit the internal bore of the component. The design of the expanding mandrel makes it possible to clamp the machined part from the inside so that the outer surface is free to work on.

Solid mandrels are used for machining the outside diameter of a part that is concentric with a drilled or bored hole. They are manufactured from rock solid steel and have flat heads with tapered bodies. The Solid Mandrels range in body diameter from 7/32” to 2-7/8” and stretch in length from 3-3/4” to as long as 13.”

Expanding-end mandrels feature an expanding end for holding and bearing the inside diameter of a workpiece. These mandrels are produced from carbon steel for quick and easy machining. The body diameter ranges from ¼” to 2” with corresponding shank diameters of ¼” to 1.”

If you’re interested in K.O. Lee Economy Mandrels or require OEM parts for your LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, call LeBlond Ltd. at (888) 920-9852.