I was at a fact-finding mission at a South Florida machine shop. The machine tool veterans talked of decades of sweat and toil in a proud industry. They ended the interview on a dramatic note. I should explore in our newfangled blog how NAFTA killed the American machine tool industry.

When the trade accord between the United States, Mexico and Canada passed in the Clinton era, you could hear the sucking sound of jobs being shipped south to confirm the fears expressed by candidate Ross Perot in the 1992 U.S. Presidential debate, according to these machine tool veterans.

Is this true? Did NAFTA kill the American machine tool industry?

The simple answer is no. The more complicated view is that NAFTA did have an effect on the American machine tool industry and manufacturing in general.

First of all, what is NAFTA?

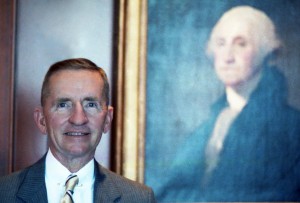

We posed this question to Christopher Wilson, Associate at the Mexico Institute of The Woodrow Wilson Center, a Washington DC-based think tank. Wilson is an expert on United States-Mexico economic relations. Here, he describes NAFTA and its broad macro-economic effects:

NAFTA is a trade and investment agreement. The trade-side being the biggest element of what it did. It lowered tariffs on most goods that are traded between the United States, Mexico and Canada. As a result of lowering some of these barriers for trade, the amount of trade between these three countries has grown enormously. It’s now five times bigger than it was pre-NAFTA.

The effect of NAFTA on the U.S. machine tool industry was a wash.

The changes in the tariff structure for the industry were “not particularly big,” according to Wilson. Mexican machine tool companies received a “slight advantage” selling to the American market. The machine tool industry in the United States gained significantly from increased exports to a manufacturing sector gaining traction in Mexico.

The American machine tool industry has greatly benefitted from what Wilson terms “re-regionalization,” a relatively recent trend and “second wave of globalization” where the manufacturing sectors of all three NAFTA countries are more closely integrated.

The auto industry is an example. A “screw widget” is produced in Mexico and shipped to Canada and placed in a fuel injector. The fuel injector is then shipped to the United States and placed in a finished vehicle.

“This ‘back and forth’ is something that is pretty unique to North America,” Wilson explains.

“It doesn’t always make sense for American manufacturing companies to chase cheap wages around the world. It also makes sense to keep manufacturing closer to your market because of transportation costs and logistics of supply chains.”

In other words, American manufacturing, a big market for the local machine tool industry, is coming home.

If you’re interested in a new LeBlond lathe or K.O. Lee machine or interested in original OEM parts for LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, call LeBlond Ltd. at (888) 532-5663.

Congratulations to the author. Very informative in an easy to read format (not too wordy).

I’m glad to see the industry is returning to the USA, where it belongs.

I’m going to study your product lines,. We’re in the midst of an expansion and we would prefer US service and supply capability.

TELL us what did America look like before NAFTA, what does it look like today! stop picking and choosing with just tool shops and NAFTA. NAFTA took this country apart and created a cheap service industry of soda jerks and grill cooks , tell all of us what happened to our tax base!!!!!!!!!

At the risk of responding to a glib quip with the enarestly obvious, I’ll note:- Layton never claimed NAFTA has led to manufacturing jobs going to China.- He wouldn’t be entirely wrong if he did. Trade deals like NAFTA prevent Canada from developing national economic policies – that means we lose jobs not just to the US and Mexico but to the entire world. That was the reason why the Liberals campaigned against Free Trade in 1988 and against NAFTA in 1993. Of course, it was subsequently revealed that they were lying through their teeth – but, at the time, a lot of Canadians were moved by the argument.- For the record, when Jean Chretien was lying during the 1993 campaign he had the support of Ross Perot and Pat Buchanan. Liberals didn’t complain then about the strange bedfellows.- And since we’re talking about who is on who’s side: it’s worth noting that on this issue Layton is onside with Hillary Clinton and Barrack Obama. And Stephane Dion’s onside with Stephen Harper and John McCain.